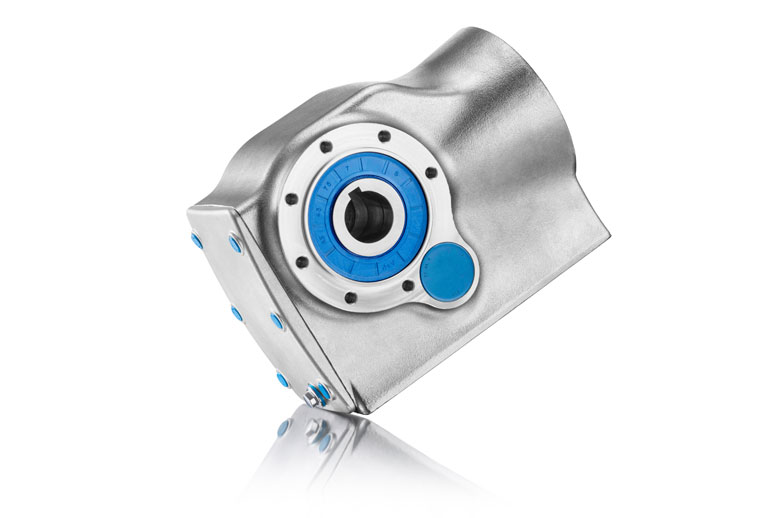

Stainless steel gear motors

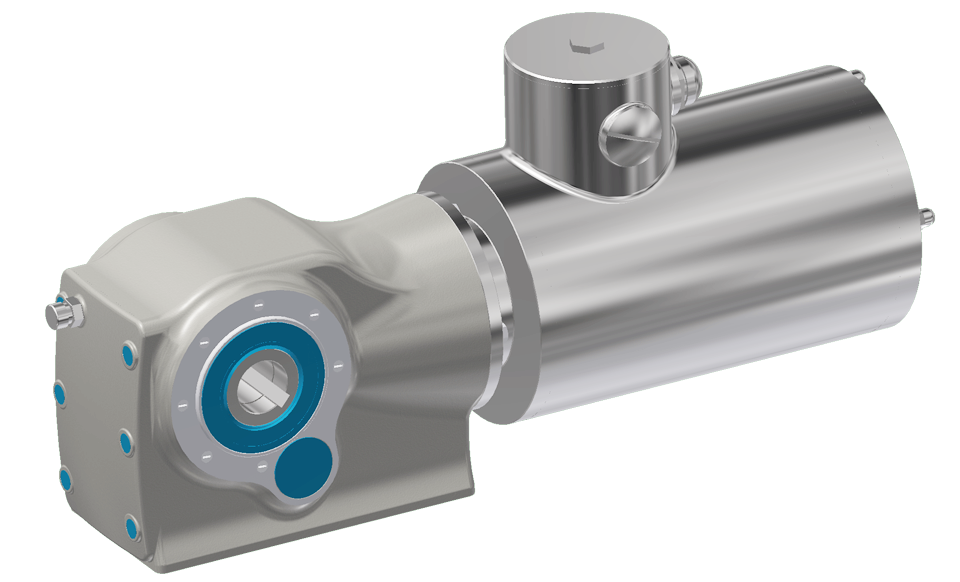

Dertec’s stainless steel gear motors are engineered for tough industrial environments where hygiene, reliability, and long-lasting performance are essential. Designed with easy cleanability and certified to IP67 and IP69 standards, our gear motors are trusted in the food industry and beyond. Their seamless integration of a stainless steel gearbox and electric motor ensures optimal performance under the harshest conditions.

Dertec® gear motors are custom-assembled to match your specific requirements

Stainless steel gearbox option

From bevel and hypoid gearboxes to worm, helical, and parallel shaft configurations—all can be combined into a custom gear motor.

Stainless steel motor options

High-efficiency AC stainless steel motors in asynchronous and synchronous versions for superior performance in harsh applications

Dertec, Designed to perform

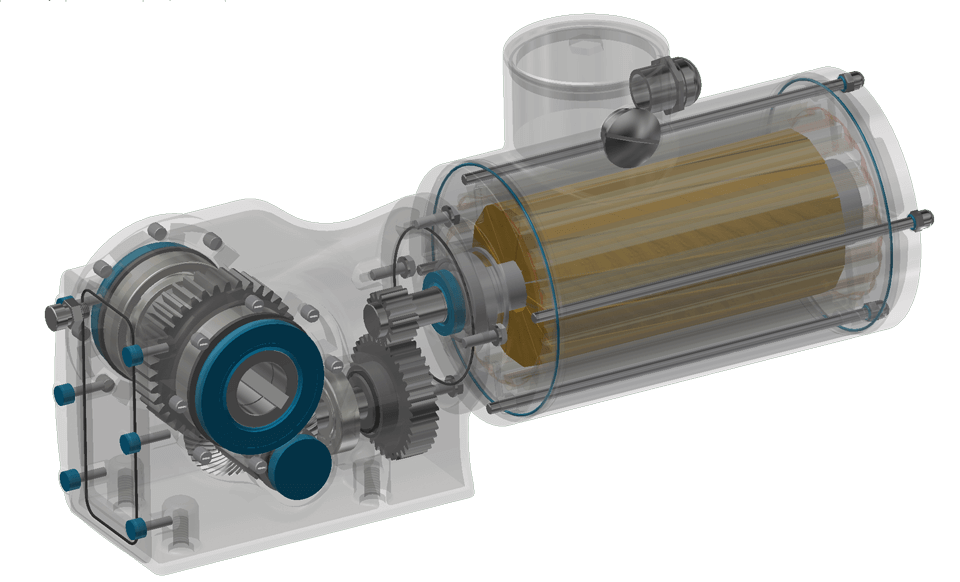

What is a stainless steel gear motor?

A gear motor is a compact unit combining an electric motor and a gearbox. This design enables power transfer, speed reduction, and increased torque, making it ideal for applications requiring precise mechanical movement. At Dertec, we assemble our stainless steel gear motors using AC asynchronous or synchronous motors paired with high-quality gearboxes, ensuring maximum efficiency and reliability.

Types of stainless steel gear motors we offer

Our gear motors are custom-built to fit a variety of applications. We offer:

- Bevel gear motors: Compact and efficient for high-torque tasks.

- Hypoid gear motors: Quiet operation with high efficiency.

- Worm gear motors: Ideal for heavy loads at lower speeds.

- Helical gear motors: Perfect for continuous-duty applications.

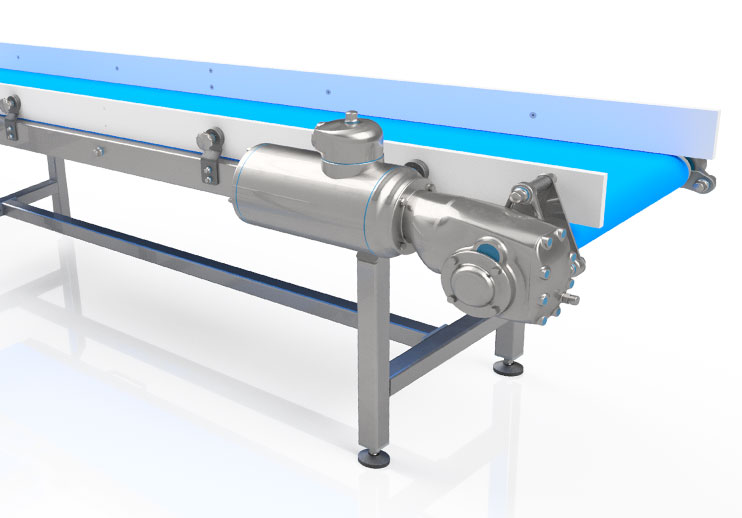

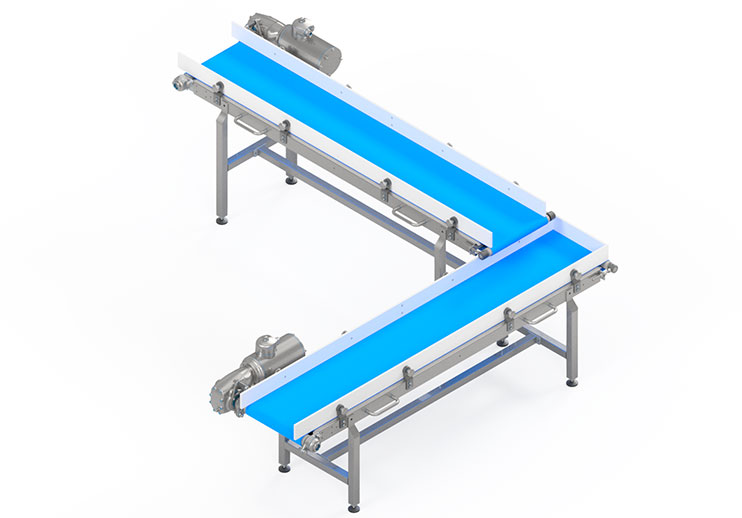

- Parallel shaft gear motors: Designed for conveyors and material handling systems.

Key Features of Dertec Stainless Steel Gear Motors

1. Hygienic Design

- Smooth, Organic Shape: Prevents dirt build up and allows easy cleaning.

- Electropolished Stainless Steel AISI 316: Corrosion-resistant and long-lasting.

- FDA Compliant Seals: Protects against water, dust, and contaminants.

2. Advanced Engineering

- Customizable Configurations: Motors built to your exact specifications, including custom shafts, flanges, and mounting options.

- High Torque Output: Delivers maximum power while maintaining energy efficiency.

- High IP Ratings: IP67 and IP69 ensure maximum resistance to high-pressure washdowns and challenging industrial conditions.

3. Exceptional Durability

- Duplex Stainless-Steel Shafts: Offer superior strength and durability.

- Special Surface Treatment for shafts: Increases surface hardness for extended service life.

- High-Temperature Shaft Seals: Engineered for demanding environments and continuous operation.

How do stainless steel gear motors work?

The working principle of a gear motor is based on the interaction between the electric motor and the gearbox. Here’s how it functions:

- Torque Conversion: The gearbox transmits the motor’s force from the input shaft to the output shaft, converting motor speed into torque.

- Gear Ratio Adjustment: The gear ratio determines how much the motor’s speed is reduced and how much torque is increased. A higher gear ratio means lower speed but greater torque, while a lower gear ratio provides higher speed with less torque.

- Load Adaptability: Depending on the gear ratio and motor type, gear motors can handle light, medium, or heavy loads, making them ideal for continuous or intermittent operation.

Applications for stainless steel gear motors

Our gear motors are trusted in a variety of industries, including:

- Food and Beverage Processing: For mixers, conveyors, and packaging machines.

- Pharmaceutical Production: Ensuring hygiene and reliability in sterile environments.

- Marine and Offshore: Withstanding harsh, saltwater conditions.

Their durability, corrosion resistance, and hygienic design make them the perfect choice for demanding industrial environments.

Learn more about Dertec’s gear motors and stainless steel solutions

With years of industry expertise, we deliver complete drive and gear motor solutions for demanding production lines. Contact us today or explore our solutions below.