Engineering Solutions.

Dertec drive technology

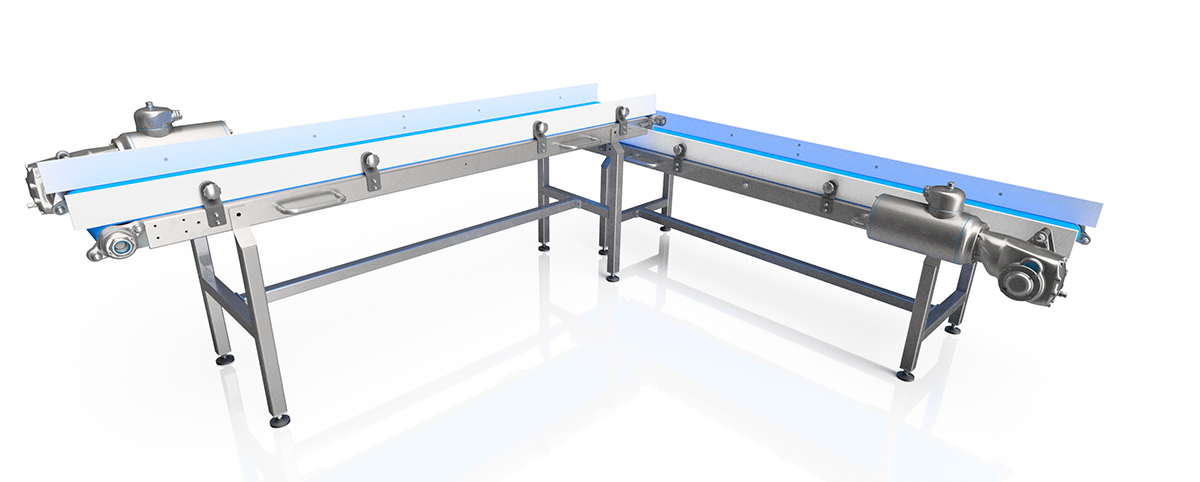

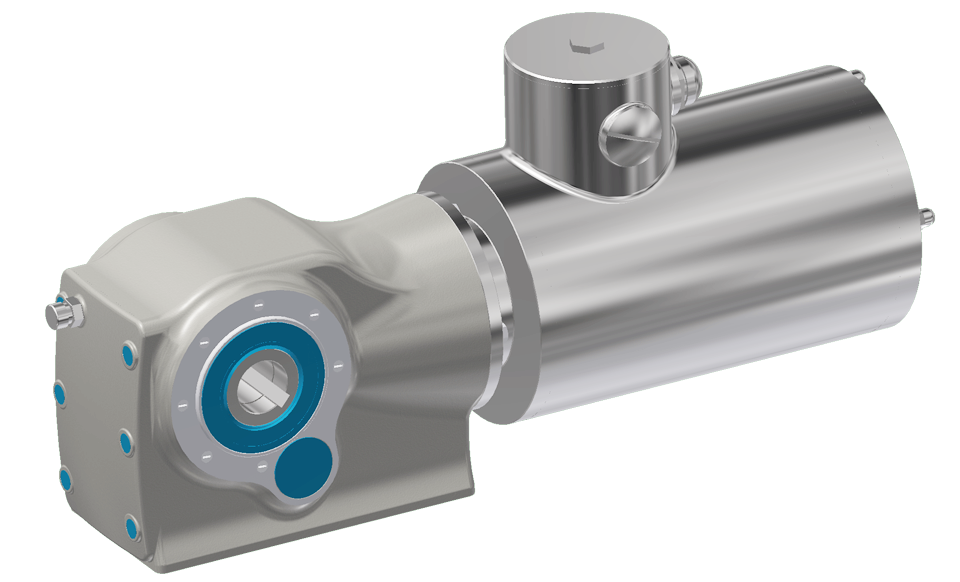

Dertec’s production program includes the widest possible variety of stainless steel drives, with each product individually designed to achieve the highest possible level of hygienic design. To safeguard the values of the Dertec design language, we ensure that each model or concept is tested according to clear hygienic criteria.

Reliability through field-driven innovation

“Engineering doesn’t stop after the theoretical approach” is a saying which applies significantly in the hygienic and sustainability branch. At Dertec we strive to connect with our customers. Monitoring the latest hygiene, sustainability trends and design solutions, will result in a big advantage at our engineering department. Our product team defines their research through a practical and an on-site knowledge basis. By pilot testing our drives in extreme environments, we improve with constant feedback from the actual place of operation.

A continuous process of improvement is based on feedback obtained by testing drives under extreme conditions and in real-world situations. Achieving a hygienic design and efficient product use is a challenging task. Dertec applies a minimalist design approach to optimize water and dirt drainage.

Hygienic design and maximum user-friendliness

Due to increasing awareness and rising customer demand for hygienic and sustainable drive solutions, Dertec designs its products with maximum efficiency and cleanability as a starting point. We use smooth surfaces, cleaning-friendly designs, and high-quality stainless steel such as AISI 304 and 316.

Finding the right balance between hygiene and ease of use is a challenge. That’s why Dertec applies a minimalist design approach to prevent dirt accumulation and ensure easy cleaning. With one of the world’s largest ranges of stainless steel drive systems, every model is designed with hygiene as a core value and tested according to strict hygiene standards.

Reliability starts with precision

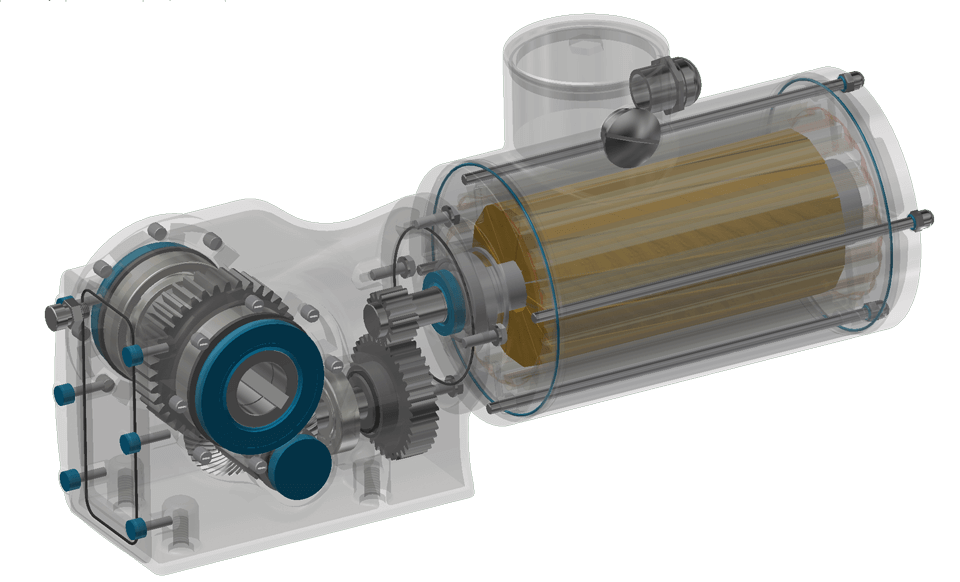

To ensure absolute reliability, our stainless steel gearboxes and motors are manufactured and inspected with the utmost precision. Using an advanced Zeiss CMM measuring machine, we verify at the micron level whether all dimensional tolerances meet the required standards. This not only guarantees a perfect fit and watertightness (IP66/IP69K), but also ensures minimal wear, reduced maintenance, and an exceptionally long lifespan — even under the most demanding conditions.

Wide variety

Dertec does not only focus on the most popular drives. Through the years we have engineered the most common gearboxes for the automation industry. We handle up to 2700 Nm output torque in stainless steel. No less than 29 different types divided over 8 product lines can be supplied to meet your needs. Please feel free to contact us for bigger or smaller Stainless steel gearboxes, we will be happy to study a suitable solution for your specific application.