Important information regarding the protection classes (IP) of electric drives in the food industry

The increasing demand for IP69 is understandable. Although in practice this need often arises from a lack of knowledge and from a lack of the correct seals which are suitable for keeping water and contaminants out. The idea that IP69 is better than IP66, IP67 or IP68 is a widespread misunderstanding and may be traced back to the simple fact that only the number 69 is higher than 66, 67 and 68.

IP67 does not mean waterproof, IP68 does not mean waterproof, nor does IP69k imply waterproof. These IP ratings deal with how products are tested and how well they stand up to the ingress testing in regards to dust, dirt, water, body parts, foreign objects, etc.

Note: During the test procedures, the products (Drives) are not electrically connected and are not loaded. The own temperature of the drive is comparable to the existing ambient temperature. It is nothing more or less than a physical test on the used parts. Also they are being tested only in one position which could be different from the intended use.

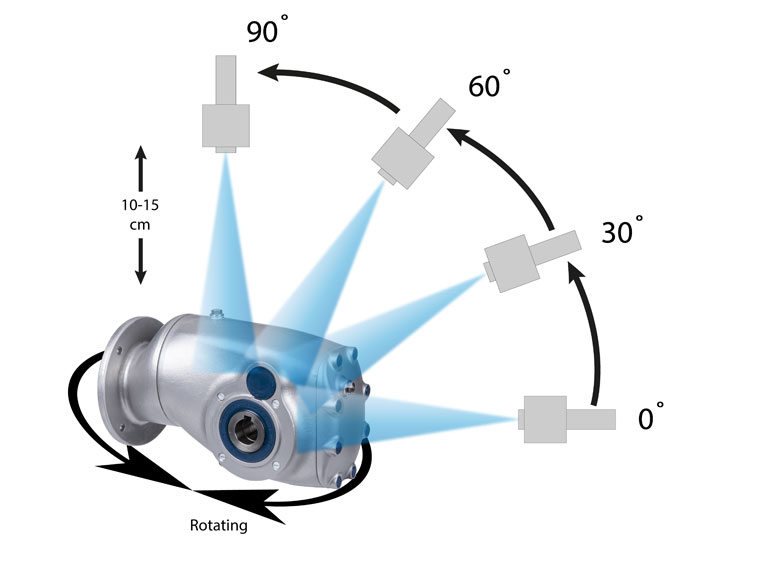

Products with an IP69K rating undergo a challenging set of tests to ensure that they certainly offer adequate protection against high pressure and high temperature. The water penetration tests themselves are done by placing the product on a turntable with a rotation speed of 5 ± 1 revolutions per minute. The product is then tested by spraying water at a short distance (100 to 150 mm) at a rate of about 14-16 liters of water per minute with a water pressure between 80 – 100 bar, at a temperature of 80°C. Jet duration is only 30 seconds at each angle.

With all due respect to the existing standards, the end user has only one wish: they want a drive that is sufficiently protected against the ingress of moisture and dirt during use and cleaning.

The majority of drives in the food industry are not used in underwater / submerged conditions and the actual use is a combination of dripping water from the production lines and high pressure cleaning during standstill after production.

For dripping water situations only, the IP66 classification could be suitable, however in many cases the actual situation is different from ideal IP testing conditions.

While the drives are hardly warmer than the ambient temperature during the IP test, they have a higher own and surface temperature during actual use. It is therefore advisable to let the drives cool down first. In practice, however, most drives are cleaned soon after standing still. The enormous temperature difference that then occurs, sometimes up to 70 Degrees difference, causes suction of water and moisture in the enclosures.

These circumstances are different from the IP test standards. As a result it can be said that the IP entry is incorrect or is not being applied correctly on the drives. Actually it can be said that the IP test is not correct for drives in Stainless steel….

The properties of SS geared motors are different from static products. It must be borne in mind that the drives are warmer during use than during the test cycle. A large part of the leakages that occur result from these temperature differences and are then "falsely", for lack of better, placed under the IP norm.

When cooling down during hosing and cleaning the internal pressure of the drive drops. Suction caused by this pressure difference causes water suction into the drive.

IP69 does not prevent the suction of water due to pressure differences, IP69 helps prevent water ingress due to high pressure cleaning of the drive but according to the applicable standard only for a short period of only 30 seconds.

Dertec Drives have a combination of IP67 and IP69. High pressure cleaning according to the norm, waterdripping over the drive or motor according to IP67. However we do not recommend to use the DERTEC drives under water.

Pooled motorshaft

Pooled motorshaft

Note: Drives running with the outputshaft running vertical up in “pooled” position can be rated IP69 but need extra attention on the seals. Even with IP67/IP69 we cannot guarantee this mounting position without extra measures.

Dertec offers various solutions for motors where the driveshaft is used vertically. (Pooled) You are kindly invited to ask for the solutions we can offer for this vertical driveshaft use.